China Enamel Cast Iron Cookware Manufacturer

Shijiazhuang Zhengzhong Technology Co., Ltd (also named Center Enamel) was established in 1989, we are the leading manufacturer of Enamel Cast Iron Cookware with more than 30 years of experience. Our factory is ISO9001-2015, BCSI and Facility Security certified, our products satisfy the food-grade testing requirement such as LFGB, DGCCRF, California Proposition 65 etc.

We have wide ranges of cast iron cookware, including Casseroles, Dutch ovens, Grill pans, Fry pas, Skillets, Saucepans, Serving Dishes and more in classic and trendy designs. The enamel glaze used for coating our cookware is formulated and produced by our own company or from the well-known enamel brands. We are happy to produce the products for our customers, OEM or ODM orders are welcomed.

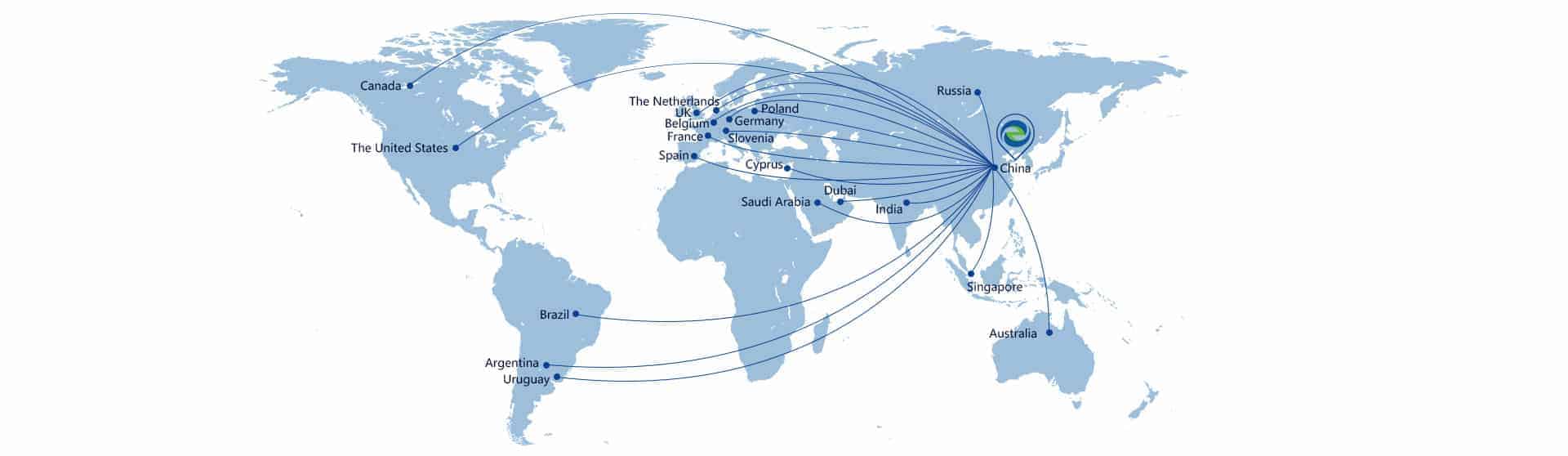

Our products are hot selling to worldwide to more than 50 countries including to North America, Europe, Australia, Middle East, South East Asia etc marketplaces and domestic market, with major customers including famous brands, TV shopping companies, chain stores, supermarkets, hypermarkets and capable importers and so on. We look forward to the close cooperation with more partners and customers all over the world!

Enamel Cast Iron Cookware Production Process

Enamel Frits

Our enamel frits is a independently developed and produced. Our company is the supplier of China's largest small home appliance group, Midea. The glaze developed by our company is in full compliance with food safety requirements.

Foundry

More than 90% of the orders in our company are machine-made. The machine casting blank has the following advantages:

1.strong tightness;

2.good molding, not deformed easily;

3.more suitable for enamel coating;

4.the delivery is more secure.

Polishing

Grinding is for the purpose of polishing the uneven surfaces, flying edges, burr, etc., so that the casting surface is flat. And our examination to the polishing is one by one.

Blasting

Blasting is for the purpose of cleaning the impurities adhered on the surface of the cas- ting, making the castings' surfaces smooth, and be suitable for the techniciansto burn.

Spray and Enameling

There are three times for the spraying of full-color products in our company:one time bottom glaze, and two times surfaceglaze. The matte glaze at the socket is the special glaze.The bottom glaze firing temperature is generally controlled at 770 to 790 centigra- de, whereas the surface glaze firing temperature is generally controlled at 740 to 765 centigrade.

Inspection

Normally our inspections include thermal shock test, hitting of steel balls test, acid test and appearance inspection.

Enamel Cast Iron Cookware For Global Customers

Enamel cast iron cookware are mainly sold to the the USA, Canada, Europe, Australia, Middle East, South East Asia and domestic markets.